Different Qualities Of Concrete

As more engineering and building experts learn that maintaining a building over time consumes significantly more effort than constructing it, there will be a more need for longevity and energy performance.

Concrete is being chosen by designers, engineers, and constructors for its durability, recyclable elements, and energy performance not available in other construction materials such as steel and wood. Concrete is a sustainable construction material that is also a good choice for long-term development.

What are the Different Qualities Of Concrete?

Besides all the benefits, we are going through different qualities of concrete that can help you make a better decision whether you should use it or not. They are as follows:

- Ecological Qualities

- Sturdiness

- Concrete Hardens at Ambient Temperature

- Production Energy Saving

- The Property to be Shaped by Molding

- Features of Great Water Resistance

- High-Temperature Support

- Waste Consumption and Recycling Capability

- Reinforced Concrete Usage

- Creep

- Little or No upkeep is Needed

- Utilization with Multiple Modes

Ecological Qualities

Concrete is environmentally friendly. As a building material, concrete serves to maintain our natural resources while also providing distinct advantages to customers, from houses to business buildings to roads. Concrete has much to give in terms of ecology.

Concrete is beneficial to the environment in a large number of aspects. Its constituents (water, aggregate, and cement) are plentiful and need less energy to produce than other building materials. Quarries' principal source of raw materials can be quickly recovered for recreation, residential, or commercial usage. They can also be returned to their original form.

Being a practically inert substance, concrete is an excellent medium for recycling trash or industrial wastes. Most materials that would otherwise wind up in landfills can produce concrete instead.

Materials such as blast furnace slag, recycled polystyrene, and fly ash can be added to the concrete formula to improve its attractiveness. Waste items such as scrap tires and kiln dust are utilized to power the cement manufacturing process. Even old concrete can be reincarnated as aggregate in fresh concrete compositions.

Sturdiness

Concrete structure outlasts all other building materials. This is due to the fact that concrete actually strengthens with time. When you construct using concrete, you don't have to be concerned about long-term expenses or the environment due to repair and maintenance. The truth that you won't have to pay routine maintenance lowers the overall cost of ownership.

Concrete is fire, rust, and rot-proof. It is also resistant to vibrations, water, wind, and earthquakes. This not only saves money, but it also keeps the people safe. When it comes to environmental calamities and harsh weather occurrences, concrete has been shown to be the most resilient construction material.

Concrete Hardens at Ambient Temperature

Concrete forms harden and acquire strength at a typical room temperature or ambient temperature. This is due to the fact that cement is a low-temperature bonded inorganic substance. As a result, concrete can be utilized regardless of the weather and, if necessary, optimized using admixtures.

Production Energy Saving

In contrast to steel, the quantity of power needed to manufacture concrete is less. Plain cement concrete requires just 450–750 kWh/ton of power, whereas reinforced concrete requires 800–3200 kWh/ton. The creation of structural steel requires 8000 kWh/ton or even more, which is over 3-10 times the energy usage.

The Property to be Shaped by Molding

New concrete is flowable and liquid in form. Concrete can thus be placed into different molds or shuttering arrangements on the construction site to form specific shapes and sizes. By modifying the mixture, concrete can be formed into complicated forms and patterns.

Features of Great Water Resistance

Water-borne chemicals can cause corrosion in concrete and reinforced concrete. Concrete, unlike wood and steel, can endure water without damage. Due to this quality, it is perfect for underwater and submerged uses such as structural systems, pipes, dams, waterways, linings, and waterfront constructions. Pure water is not harmful to concrete or reinforced concrete. However, chemicals added to water, such as sulfates, chlorides, and carbon dioxide, induce corrosion.

High-Temperature Support

Concrete is more resistant to extreme temperatures than steel and wood. The principal binder in concrete, calcium silicate hydrate, C-S-H, can resist temperatures up to 910 degrees Celsius. Although concrete is a poor heat conductor, it can store a significant quantity of heat from the surroundings. Concrete can endure the heat for 2–6 hours, giving enough opportunity for rescue missions in the fire situation. And is used in high temp and blast situations to fireproof steel.

Waste Consumption and Recycling Capability

Most industrial byproducts can be repurposed to replace cement or aggregate. Fly ash, slag, waste glass, and even ground automobile tires in concrete are examples of such materials. As a result, concrete manufacturing has the potential to drastically minimize environmental consequences caused by industrial waste.

Using these wastes enhances the qualities of concrete, ensuring that the structure's quality is not endangered. Concrete is utilized on an as-needed premise, whether cast-in-place or pre-cast. Leftovers can be reused or recycled. Furthermore, concrete is a long-lasting product that increases durability with time, saving energy by lowering care and the need for rebuilding.

Reinforced Concrete Usage

Concrete has a value of thermal expansion similar to steel. "1.2 × 10−5 steel and 1.0–1.5 × 10−5 concrete" Because of the presence of CH and other alkalis, concrete protects the steel in corrosive situations. Furthermore, concrete helps to increase the tensile durability of reinforced concrete parts and structures.

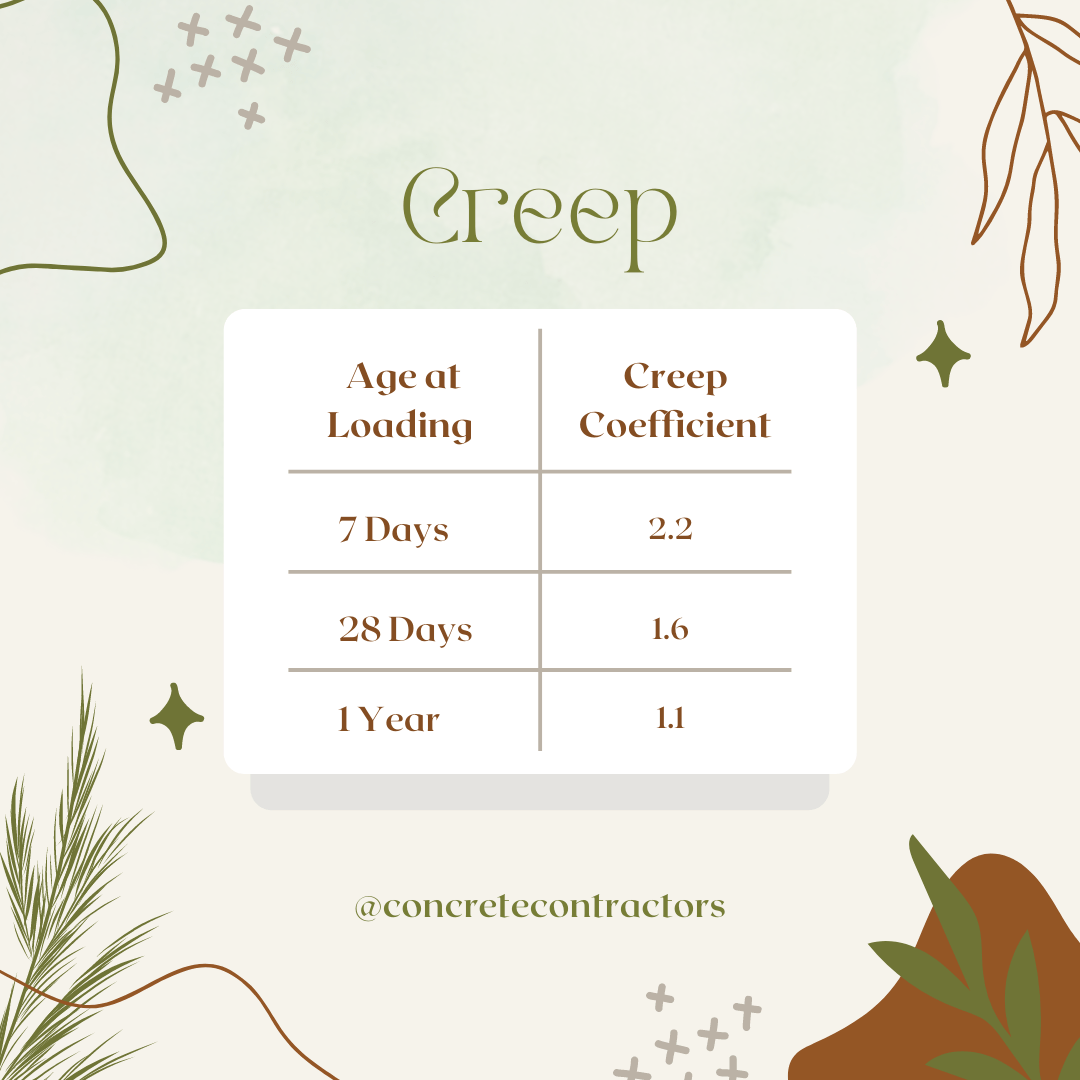

Creep

Creep is defined as the plastic distortion that occurs over time due to a sustained load or tension. The pace of creep is reducing overtime, and it has nearly halted after five years. Concrete creep increases with early stress or loading, soft and lose particles, and inadequately compacted concrete. Creep values must be obtained at the location with trials, according to IS 456: 2000 paragraph 6.2.5.1. These values can be utilized in the absence of experimental data.

Little or No upkeep is Needed

Unlike steel or timber buildings, where weathering is unavoidable, concrete structures do not need a protective layer or painting for regular treatments as weather protection. The coating will be renewed and refinished on a regular schedule, resulting in significantly reduced upkeep costs for concrete than steel or wood.

Utilization with Multiple Modes

One of the most significant benefits of concrete is its capacity to be employed in various construction approaches. Concrete is manually applied, poured, pumped, sprayed, grouted, and utilized in complex techniques such as tunnel shotcreting.